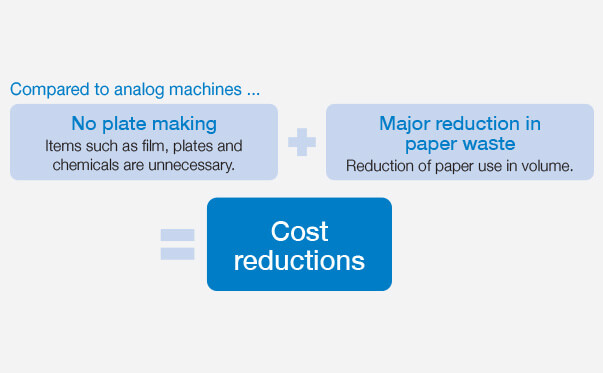

Ease of Tasks such as Color Adjustments and Reprinting compared to Analog Machines

Compared not only to flexography, but also liquid development and inkjet printers, AccurioLabel 190 ensures ease of maintenance. Tasks that take time on analog machines such as color adjustments can be performed with ease on a digital machine. The ability to perform operations simply by following on-screen instructions makes it possible to operate the machine with little time needed for training.

Mouse-compatible operation panel

The large 15-inch display adopted is easy to view and operate. The angle of the panel can be freely adjusted to suit the user and the easy-to-understand GUI and guide messages ensure high operability when making settings. A USB mouse can also be connected to improve operability.