50-sheet booklet making with front trimming and optional creasing, slitting and spine corner forming

102-sheet auto ring binding

Perfect binding for books of up to 30 mm

100-sheet stapling with cutting mechanism

For highest automation and enormous productivity

For more profit in the printroom

AccurioPress 6136/6136P/6120

Up to 136 A4 pages per minute

Up to 74 SRA3 pages per minute

Up to 7,940 A4 pages per hour

Up to 4,274 SRA3 pages per hour

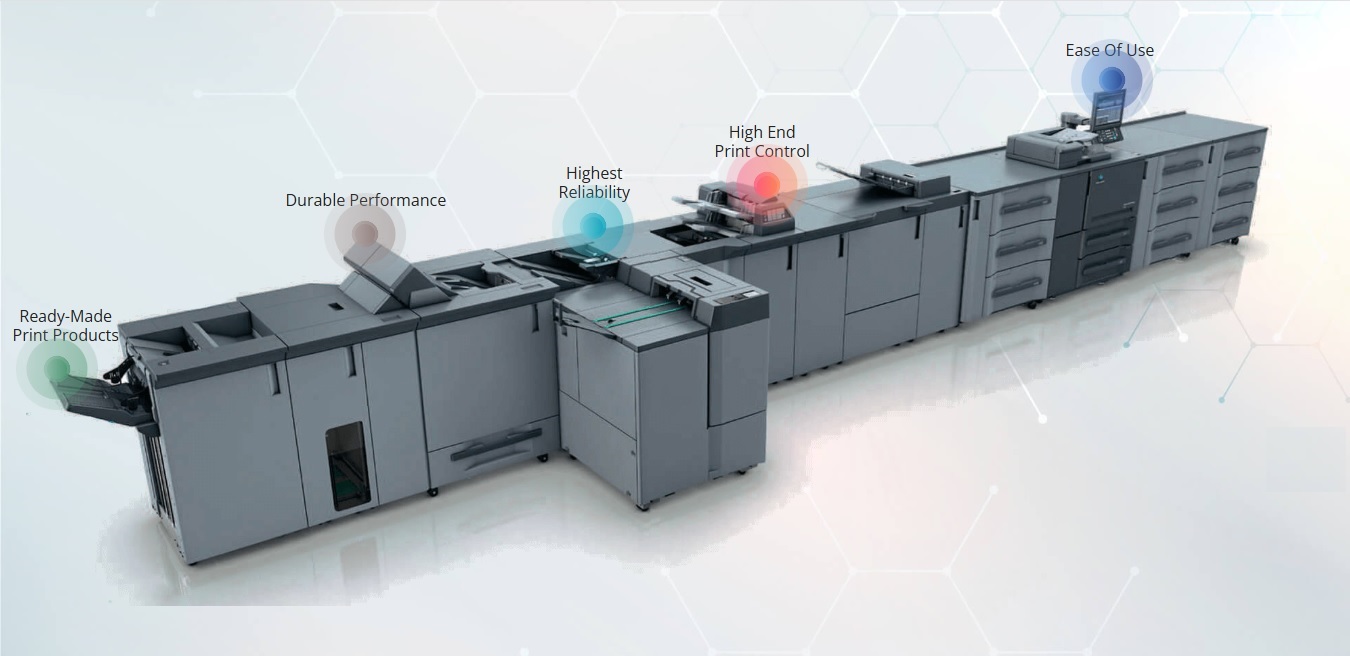

Long-life platform, long-lasting parts and consumables

Optimum registration results via ICCU

Belt transfer system

For prints with maximum efficiency

For lucrative short-run printing

Proprietary Konica Minolta controller

For intuitive operation

Saves time and money

Simple paper catalogue settings

Easy-to-follow on-screen instructions

Operator Replaceable Unit Management (ORUM)

For maximum ease of operation

Frees operators for more important jobs

AccurioPress new series of high-end monochrome production press, accelerating offset transfer, pursuing work efficiency, with the highest class productivity/reliability/labour saving.

A variety of functions of the AccurioPress 6136 series to meet the needs of professional users

- High productivity and durability corresponding to high volume printing

- Intelligent quality optimizer that responds to high quality and short delivery time demand

- Flexible paper handling ability to expand print service area

- High image quality not limited to applications

- High function finisher group that contributes to improvement of work efficiency and short delivery time

- Excellent operability · Optimum workflow construction

Intelligent Quality Optimizer

Automatically corrects density and gradation and front and back registration during printing and printing, and supplies high quality printed matter quickly and stably.

Cardboard printing up to 350g/m 2

It will contribute to expansion of printing services such as package printing, overprinting business cards with thick impact paper and printing price tags.

Support for thin paper of 40g/m 2

Contracts, low-cost leaflets, invoices printing etc are expanded. It is also possible to propose low cost printing using thin paper.

Stable paper feeding performance

It adopts an air suction paper feeding system and it is effective not only for heavy paper loads with heavy load but also for slipping offset printed overprinting applications.

Low cost envelope printing

By using the dedicated fixing unit for envelope printing, stable transportability is realized. We can also use general-purpose envelopes affixed to center, realizing a low cost printing environment.

High quality saddle stitch binding

By attaching SD – 513, you can print saddle stitch of up to 200 pages in class, and high – quality binding with square backing function and three – way cutting (slit) function is possible.

Heavy walnut binding

By using PB – 503, case binding of up to 600 pages in class is possible. Since bookbinding can be done without cutting, efficient bookbinding is possible without using nobby size.

Various folding functions

FD–503 supports various folding functions. Efficient printing environment can be obtained without offline work such as simple flier, DM, Itinerary, etc.

Konica Minolta Accurio Series Contributing to Improve Your Business

The Accurio series of Konica Minolta is a new brand product group that comprehensively supports the growth of the printing business. We will support the further realization of production efficiency, cost reduction, high quality and expansion of printing services in the professional digital printing industry that continues to expand. In addition to the electrophotographic professional printing system, a comprehensive solution such as high-end inkjet press with state-of-the-art technology and industrial printing system, and workflow solution and cloud-based color management tool that make maximum use of them We will promote automation, efficiency improvement and quality improvement strongly.

High productivity · Excellent durability

High-speed color scanner is installed to productivity which becomes the highest class level with A3 size which is used frequently. In addition, it is robust design adopting a high rigidity frame and it works well even in a hard work site. Indeed, it boasts high level productivity and reliability as a production machine.

High speed output of A4: 136 ppm, A3: 78 ppm

Improved productivity with excellent instantaneous power

A4 Horizontal 136 ppm, and A3 size achieves high productivity of 78 ppm, which is the top class. We will contribute to improvement of printing business such as quick delivery time service important for on-demand printing, response to sudden order.

- * 6120 is A4: 120 ppm, A3: 70 ppm

Adopt high speed color scanner

Streamline data archiving business

Speed scan at maximum 240 faces/min (300 dpi duplex scanning) by 1 pass double sided simultaneous reading. We strongly support data archiving business such as schools, government offices, law firms, etc. We respond to diversified applications not just printing business.

- Standard on 6136/6120

Large capacity toner bottle

Interchangeable even during printing

Approximately 10.5 thousand sheets *1 equivalent of toner bottle that can be outputted. It eliminates the trouble of replacement due to the large capacity, it is also possible to exchange during printing. Reduce downtime and improve occupancy rate.

- *1 A4 size, printing rate 5% When text document is copied

Adoption of high rigidity body

Reliability as a production machine

Rugged and highly durable metal frame body adopted. It demonstrates stable reliability even in continuous operation. Consumables have realized long life, contributing to reduction of exchange frequency over long periods.

High feed / discharge capacity

Supports high volume printing

Up to 3 connections are possible for the large capacity paper feed unit PF – 710*1. Together with main unit feeding, up to 18,000 sheets can be fed continuously. In addition, it is possible to connect up to 3 sheets of paper discharge unit LS – 506*1, boasting a maximum discharge capacity of 15,000 sheets. With these high paper feed / discharge capabilities, we support high volume printing.

- *1 option

- Paper supply capacity is 80 g / m2 when paper

Large capacity output tray OT – 510 Type B

Large capacity & low cost delivery unit capable of stacking up to 4,200 sheets. With efficient paper discharge capacity, we will streamline the work process in workflow mainly for offline post-processing.

Excellent operability

A 15-inch large-size touch panel with excellent visibility and operability greatly improves working efficiency with unified UI display with color machine. Furthermore, it carries advanced job management that supports operators, which leads to simplification of output work and labor saving.

Unified color machine and operation panel

Seamless operation realized

The user interface of the operation panel is unified by color machine and monochrome machine. Improve operation training at the time of introduction and workability after installation.

Up to 256 types of paper profiles that can be registered

Seamless operation realized

For each paper tray, size setting, air blow setting, paper condition selection are available. Since the optimum process settings for each paper can be called immediately, you can change the paper efficiently with job switching. Up to 256 profiles can be registered in the paper condition selection.

Job Ticket / Page Edit

Improve operational efficiency with fine-grained setting

You can check and edit the details of the job ticket. It is also possible to display the output image with the edited job ticket and to output the sample for confirmation. Flexible job management improves efficiency of complex and precise output tasks.

Color Centro (standard equipment)

Easy to use and flexible utility

Equipped with the same color management software Color Centro as the color production machine as standard. From the PC you can adjust the tone curve to “image” and “text / graphic”, respectively, and more flexible image quality adjustment is possible.

AccurioPro Print Manager (Standard equipment)

Seamless and easy to use interface

The function equivalent to Job Centro which was installed in color production printing system and so on became available in the web browser. It is an easy-to-use interface with high affinity with the main body panel and printer driver, making the operating efficiency more efficient. It also has a tone curve adjustment function equivalent to Color Centro.

Direct print

Easy output with hot folder

Just drag & drop PDF / TIFF file to icon or shared folder, you can print without starting application. If you create multiple icons of frequently used print settings, you do not have to reset each time you output, it’s very quick and convenient.

- * Direct printing is possible with both AccurioPro Hot Folder and the main body function.

High Resolution

It provides exposure with 1200 dpi of LPH, smooth photographic image quality by adopting digital toner HD, CIE color space, and high character quality. With excellent image quality, we offer high quality printed products for various purposes.

High resolution output of 1200 dpi

Write by LPH (LED Print Head)

Adopt LED printer head to write using LED unit. A fine 30 μm beam diameter achieves a high resolution of 1200 dpi, greatly improving reproducibility. We are further enhancing the quality of fine letters and screen gradations.

Digital toner HD

Both high image quality and environmental friendliness are compatible

Six types of dot screen covering from 85 L (low resolution) to 210 L (high resolution), and 9 kinds of screens of 3 kinds of FM screens are standard equipment. We reviewed the shape of individual halftone dots and realized smoother high image quality. By using the optimum screen according to the output content, you can provide high-quality print image quality.

9 patterns screen setting

Various screens can be selected

Adopting digital toner HD containing plant-derived ingredients as material. Since it can be fixed at low temperature, it contributes to reduction of power consumption. In addition, we consider the impact on the environment from various viewpoints during production, use and disposal.

Adoption of CIE color space

Process CMYK data appropriately

When outputting a color original, convert the input image to CIE space once. Then it converts it to the color space of this machine and processes it properly. Compared with simple conversion by conventional mathematical expressions, it suppresses color shadow of shadow part, enabling rich gradation expression.

- Output speed may decrease.

Function group supporting high quality

Adjustable curl processing according to paper characteristics and output format, and optimum transfer method to produce high quality. In addition, image rotation and skew correction function are added for front and back registration, which greatly improves accuracy. It improves the quality of the final delivered goods as well as the workability of the post-processing process.

Real time curl correction function *Option

Optimum curl adjustment without lowering productivity

With the newly developed relay conveyance unit RU – 518, it is possible to adjust fine curl in 20 steps. Curl correction can be performed in real time without interruption during printing, and flat printing reduces the load and slack in the post-processing process.

Hybrid curl adjustment function *Option

To simplify the work process and improve quality

By installing the humidification unit HM – 103 on the relay conveyance unit RU – 518, a hybrid decal system that shares mechanical and humidification can be used. Humidification will cool the paper that became hot in the fusing unit and reduce the stiffness, enabling more efficient curl adjustment. In addition, since it has not only curl adjustment but also static electricity removal effect, workability in post-offline post processing can be greatly improved.

Belt transfer method

Improve transfer quality and conveyance of paper

Tightly adhere paper to the belt to eliminate gaps, uniformly adhere toner uniformly by the pressure of the belt. Minimize transfer misalignment caused by missing images on the paper edge and resistance of the roller.

High-accuracy front and rear register adjustment function

Add image rotation and skew correction

It corresponds also to the adjustment of the rotation and skew of the image, making it possible to adjust the front and back register more accurately. Easier adjustments can be made to applications requiring high front / back register accuracy, such as business cards, shop cards, tickets.

Suitable for a wide range of paper and applications

- * The color output sample of this page is an overprint image.

Excellent paper conveyance technology that stably feeds a wide variety of paper to a wide range of corresponding paper basis weight of 40 to 350 g / m 2 . We will support business expansion by strengthening paper feedability such as offset printed paper, envelopes, mailing labels, etc. and identifying latent needs.

40 g / m2 of thin paper, 350 g / m2 can be printing on cardboard of

Class top level paper handling capability

40 g / m2 from thin paper, 350 g / m2 corresponding to the cardboard. Automatic duplex printing also supports paper thickness of 300 g / m 2 . We respond to a variety of printing services such as heavy letter packages and tag printing from slim paper forms with best-in-class paper handling capabilities

Air Suction Feeding *Option

Stable feeding of thick paper or offset printed paper

In addition to the air flow method, the large capacity paper feed unit PF – 710 adopts air suction paper feed, which is the same method as offset printing. It ensures reliable and reliable paper feed even for cardboard with high paper feed load and offset printed paper etc.

Low cost, high quality envelope printing *Option

Use a dedicated fusing unit

By using the fixing unit dedicated to envelope printing, high-quality envelope printing can be executed stably. It is designed to minimize the gloss of the envelope cling part, so you can use inexpensive general-purpose envelopes, which contributes to cost reduction.

Intelligent quality optimizer (option, RU – 518 is required for installation)

Skillless · Automated concentration adjustment and front / back register adjustment before printing in a short time. By greatly shortening the adjustment time, we will expand the original printing production of the machine. In addition, since concentration, front / back registration can be monitored in real time even during printing, high quality printed products can be stably supplied.

Automated density correction · front and back register adjustment

Implemented with high precision for a short time, skillless

It performs automatic density correction and front / back register adjustment before printing. It drastically reduces the adjustment time taken other than the original production time and contributes to improving the printing occupancy rate directly linked to profit. Also, manual measurement and numerical input as before are unnecessary. We will eliminate quality problems caused by measurement and input errors, provide skillless, high quality printed products.

Real time gradation correction · front and back register adjustment

Monitoring and correction in real time during printing

Automatically write gradation patches and registration marks in the margin of the printed matter, continue monitoring without decreasing productivity during printing. When a deviation from the target level is detected, it automatically corrects, suppresses the occurrence of cracks, contributes to cost reduction and improvement of customer reliability.

High function finisher that increases production efficiency (option)

Prepare a high-end finisher group that supports folding functions such as square backing, three-side cutting, crease function, saddle stitch binding, class max. 600 page case binding, quarter folding and fold folding. We will greatly contribute to reductions in personnel expenses and outsourcing expenses in CRD etc., short delivery time service, etc

T-Shape type saddle stitching unit SD-513

High-quality saddle stitch binding of up to 200 pages

A saddle stitch binding machine that adopts high quality glass clinching mechanism. It also has 4-point staple and double folding / trifold function, small edge cutting function. By adding an option, it corresponds to full bleed design by corner back processing and three-way cutting. It is possible to create high-quality saddle stitch binding. In addition, up to 4 crease functions can be added.

Multi-folding unit FD-503

Support efficient DM / brochure creation

It has various folding functions such as center folding, outer folding, inner folding, quarter folding (double parallel), Z folding and Guanyin folding, and two hole and three hole punching processing functions. Also equipped with a seat inserter function. Manual processing is also possible, so you can also work offline.

Case binding machine PB-503

It corresponds to a maximum of 600 pages

It corresponds to case binding of maximum 300 sheets · 600 pages (80 g / m 2 ) or thickness 30 mm or less. You can use thick paper up to 216 g / m 2 ※ 1 on the cover, and print and gluing process can be done inline. Simultaneous connection with the staple finisher is also possible, contributing to multiple configuration and cost saving / space saving system configuration.

- * 1 In the case of use on the cover, this newspaper is up to 91G / M 2 corresponding to

Staple finisher FS-532 Type D

Compact all-in-one finisher

100 sheets with needle cutting*1 binding staple finisher. By improving the paper discharge consistency and reviewing the paper path, it enables a beautiful finish even if the binding number is large. In addition, you can install three kinds of sub options, saddle stitching machine SD – 510, punch kit PK – 522, post inserter PI – 502 Type B, and you can extend the functions as necessary.

- *1 A3 size up to 50 sheets

Other finisher options

- PI-PFU kit which can insert a large amount of paper inserts [FA-503]

- Saddle stitch binding unit for manual and catalog creation [SD-506 Type B]

High efficiency workflow

Strengthen various linking functions. It is possible to create a highly efficient and low-cost print workflow using AccurioPro Conductor and secure printing environment with authentication cooperation. In addition, with external software linkage, we provide efficient working environment using OpenAPI and IWS compatible software.

Application compatible with office machines

Improve workability by cooperation

Corresponds to bizhub Connector for cooperation with office machines. By registering additional applications inside the main unit, you can connect to various cloud services*1 and SharePoint Server*2 from the operation panel of this machine, upload the scanned data after conversion, print directly with the external service Cooperation can be realized. Also, with OpenAPI ver.4.7*3, you can use solution applications such as authentication, billing, ubiquitous printing etc.

- *1 Google Drive, Gmail, Evernote

- *2 SharePointServer 2007/2010/2013/2016

- *3 More than 2nd version

AccurioPro Connect will be released

Workflow platform for automatic processing

We automate various work in the pre-printing process and connect them to realize automation of pre-print data processing. Perform preprocessing according to the flow specified in advance, such as various page editing and print settings, and transfer the job to the designated printing machine. Automatic processing ensures that time-consuming pre-print data processing is performed reliably, shortening processing time and greatly improving productivity. Flexible workflow construction according to customer’s environment is possible from input to printing.

User authentication

Enhanced security according to scale and environment

Authentication function that can be done by the main body alone is available. In addition, by using authentication*1 using contactless IC cards such as FeliCa used in employee ID cards, security can be strengthened without decreasing operational efficiency. It is also possible to operate in conjunction with entering and leaving management of employee ID cards, and you can choose the operation style according to the scale and environment.

- *1 An optional IC card authentication device [AU – 201 S] is required.

AccurioPro Conductor *Option

Job management solution

AccurioPro Conductor unifies management of multiple printers and automates various operations, greatly improving work efficiency. It enables seamless progress of various print jobs with different standards and requirements. We optimized the output of color machine and monochrome machine, realizing productivity improvement and production cost reduction. It has a function that contributes to reduction of total cost, such as automatic printing only monochrome pages in the document with low cost monochrome machine.

Corresponds to latest safety standards / environmental standards

We respond quickly to the new safety standard IEC 62368-1 scheduled to be enforced in June 2019 and the latest version of the International Energy Star program. We actively shape environmental efforts.

AccurioPress 6136/6136P/6120

AccurioPress new series of high-end monochrome production press, accelerating offset transfer, pursuing work efficiency, with the highest class productivity/reliability/labour saving.

Specifications

| product name | AccurioPress 6136 | Accurio Press 6120 | AccurioPress 6136P | ||

| Resolution | 1,200 × 1,200 dpi | – | |||

| Paper weight | 40–350 gsm | ||||

| Duplex unit | Non-stack type; 40–300 gsm | ||||

| Paper sizes | Min.: 95 x 139 mm Max.: 324 x 483 mm (with PF-710) |

||||

| Maximum image area | 314 x 483 mm (with PF-710) | ||||

| Paper input capacity | Standard: 3,000 sheets Max.: 18,000 sheets | ||||

| Paper output capacity | Max.: 15,000 sheets (plus sub trays)x 483 mm | ||||

| Main unit dimensions (W x D x H) | 990 x 910 x 1,454 mm | ||||

| Main unit weight | 396 kg | ||||

| AccurioPress 6136/P | |

|---|---|

| A4 – max. per minute | 136 ppm |

| A3 – max. per minute | 78 ppm |

| A4 – max. per hour | 7,940 pph |

| A3 – max. per hour | 4,526 pph |

| SRA3 – max. per hour | 4,274 pph |

| A4 – max. per minute | 120 ppm |

| A3 – max. per minute | 70 ppm |

| SRA3 – max. per minute | 66 ppm |

| AccurioPress 6120 | |

| A4 – max. per hour | 7,034 pph |

| A3 – max. per hour | 4,072 pph |

| SRA3 – max. per hour | 3,846 pph |

| Scan speed A4 | Up to 240 ppm | |

| Scan resolution | 600 x 600 dpi | |

| Scan modes | TWAIN scan; Scan-to-HDD; Scan-to-FTP; Scan-to-SMB; Scan-to-eMail | |

| Scan formats | TIFF; PDF; Encrypted PDF; XPS; CompactPDF; JPEG | |

- *1: When UK – 217 option is installed

- *2: Supports 32 bit (x86) / 64 bit (x64) environment

| Gradations | 256 gradations |

| FCOT | 200 × 200 dpi, 300 × 300 dpi, 400 × 400 dpi, 600 × 600 dpi |

| Less than 2.6 sec. (A4 LEF | Magnification |

| Multiple copies | 1–9,999 |

- *1: Supported OS of TWAIN driver

- *2: Supports 32 bit (x86) / 64 bit (x64) environment

| Integrated Color Care unit | IQ-501 |

| Air assist paper feed unit | PF-709 |

| Pre-printed paper feed kit for PF-706 | PP-701 |

| Air suction paper feed unit | PF-710 |

| Heating unit for PF-710 | HT-506 |

| Post Insertion unit | PI-PFU |

| Relay unit | RU-518 |

| Humidification unit | HM-103 |

| Multi (GBC) punching unit | GP-501 |

| Relay unit | RU-510 |

| mass | Approximately 36 kg |

| mass | Approximately 36 kg |

| mass | Approximately 36 kg |

| mass | Approximately 36 kg |

| mass | Approximately 36 kg |

| Auto ring binding unit | GP-502 |

| Folding and punching unit | FD-503 |

| Stacking unit | LS-506 |

| Booklet making unit | SD-506 |

| Booklet making unit | SD-513 |

| mass | Approximately 36 kg |

| Creasing unit for SD-513 | CR-101 |

| Slitting unit for SD-513 | TU-503 |

| Spine corner forming unit for SD-513 | FD-504 |

| mass | Approximately 36 kg |

| mass | Approximately 36 kg |

| mass | Approximately 36 kg |

| Perfect binding unit | PB-503 |

| Stapling unit | FS-532 |

| Saddle stitch kit for FS-532 | SD-510 |

| Punch kit for FS-532 | PK-522 |

| Post inserter for FS-532 | PI-502 |

| Open Stacker | OT-510 |

| Envelop fuse | EF-105 |

| Mount kit for 3rd party | MK-737 |

| Removable HDD Kit | RH-101 & HD-511 |

| Plockmatic | SD-500/SD-350 |

- All specifications refer to A4-size paper of 80 gsm quality

- The support and availability of the listed specifications and functionalities varies depending on operating systems, applications and network protocols as well as network and system configurations

- The stated life expectancy of each consumable is based on specific operating conditions such as page coverage for a particular page size (5% coverage of A4).

- The actual life of each consumable will vary depending on use and other printing variables including page coverage, page size, media type, continuous or intermittent printing, ambient temperature and humidity

- Some of the product illustrations contain optional accessories.

- Specifications and accessories are based on the information available at the time of printing and are subject to change without notice

- Konica Minolta does not warrant that any prices or specifications mentioned will be error-free.

- All brand and product names may be registered trademarks or trademarks of their respective holders and are hereby acknowledged