AccurioShine 3600

Key Features

Embellishment of

High productivity

AIS SmartScanner feature

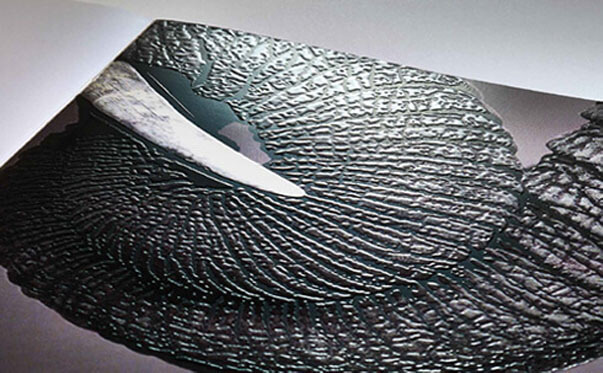

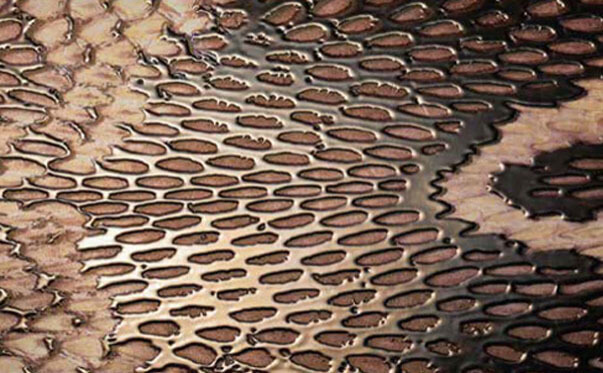

Beautiful 3D embossed effects, creating premium image and luxurious tactile finish

Product Overview

- AccurioShine 3600 is the first Konica Minolta Accurio Certified Digital Embellishment machine powered by MGI.

- The AccurioShine 3600, with its small footprint, allows any customer to have its own in-house UV digital embellishment, from prototyping to mass production, without screens, chemical solvents, plates, or tools.

- The AccurioShine 3600 uses only one type of varnish to produce 2D or 3D tactile spot UV, in fixed or variable data. Its automatic cleaning system of the inkjet heads allows to optimize its uptime with ease.

- Versatile, the AccurioShine 3600 allows the application of flat or raised varnish with tactile effect, on substrates as varied as paper, cardboard or plastic, from 135 to 450g, previously printed in digital (toner or inkjet), offset, screen or flexo printing.

- Easy to use, the AccurioShine 3600 is controlled from an onboard screen, integrating file management, cost calculator and direct retouching of spot files. The AIS SmartScanner, an artificial intelligence-driven automatic registration system, guarantees perfect registration from the very first page, and automatically corrects the registration in real time, according to any substrate deformation.

- Agile, the AccurioShine 3600 allows prints to differentiate themselves by offering to enrich printed materials with sensory and tactile effects on all types of documents: business cards, announcements, brochures, book covers, leaflets, labels, folding boxes.

- With the AccurioShine 3600, it has never been easier to enter the market of UV selective varnishing, flat or embossed, while benefiting from the quality of the technologies and the service of the world leader in the sector.

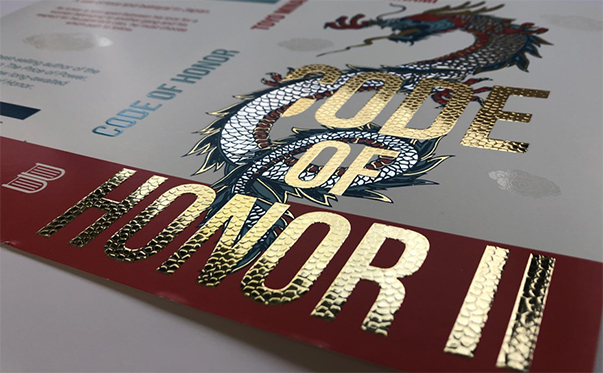

- You can choose the areas to be embellished and vary the thickness of the varnish. The combination with the iFOIL One inline hot stamping foil module opens the doors to the hot foil stamping and digital embossing market. From magazine covers, books and brochures to labels, invitation cards and packaging, you will be able to offer your customers new and exceptional services.

Customisation and personal station are increasingly in demand. Offering 2D or 3D effects can Make print jobs more profitable. Research shows that many print customers are willing to pay a Premium of up to 89% to add digital print enhancements.*1 Tactile sensation increases impulse Purchases*2 while specialty packaging has more than 46% higher quality perception.*3

- *1 Infotrends, 2016

- *2 Journal of Consumer Research, 2009

- *3 The Foil & Specialty Effects Association, 2017

Save money and space while adding a host of value-added options to offer your customers.

Compact Size, Infinite Possibilities

In-house, full-production and prototype-finishing spot UV vanishing without the need for screens, plates or dies. The AccurioShine 3600 is fully equipped to allow you to provide a broader range of finishes at an impressively small footprint.

2D & 3D Gloss Effects

Using a single varnish formula, the AccurioShine 3600 digitally produces a variety of effects on a wide range of substrate stocks and media. Create both 2D and 3D finishes on paper, plastics, synthetics and cartons from 135 to 450 gsm. Add coatings to printed materials including offset and digital inks, lamination films and aqueous coatings.

Add Impact to Every Print job

Shorter lead times and a simple job set-up make it simple to add highly profitable special effects to any print job. Optional additions including the Corona Treatment System (CTS) and Automatic PDF File Converter open the door to even more possibilities.

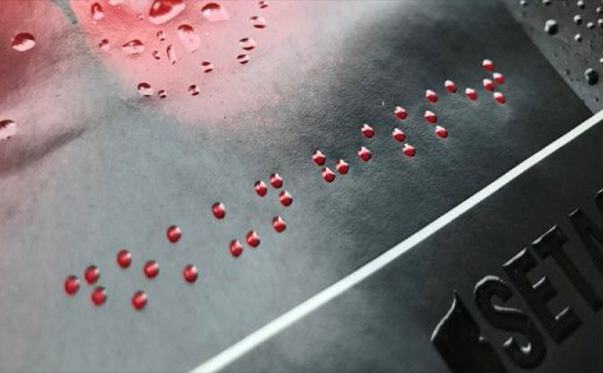

3D Braille Writing

The AccurioShine 3600 is the world premier digital embellishment machine can Produce long-lasting BRAILLE up to 300μ of thickness

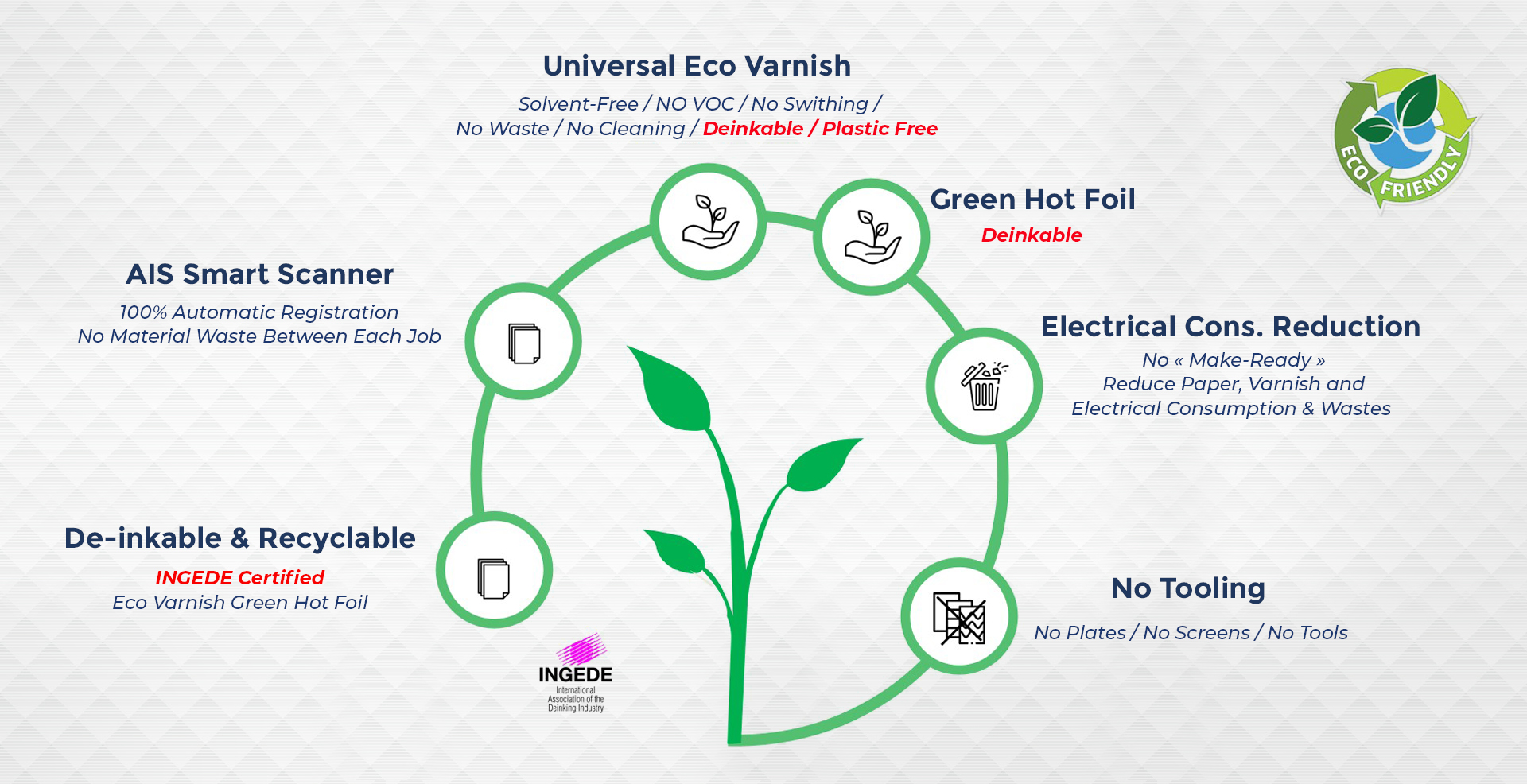

ECO-Friendly Solution

The AccurioShine 3600 features a closed/circuit system, leaves no ink or varnish residue, and is designed to prevent any cleaning or material waste between jobs, helping you to reduce paper, varnish and electrical consumption.

No plates or screens. No cleaning between jobs. With the AccurioShine 3600, all you need is a digital mask to add varnish of varying thicknesses straight on top of toner or offset prints. The Artificial Intelligence SmartScanner® reduces operator setup time by more than 80% and keeps jobs running smoothly thanks to automated correction during runs.

Use the intuitive software suite interface to manage jobs and maintenance with ease. With the job cost calculator you can evaluate images, and forecast varnish consumption and costs before production starts. Edit job files directly at the workstation using the spot varnish editor, an easy-to-use graphical tool that enables operators to modify jobs without going back to prepress. Reduce preparation times down to just a few minutes and start jobs with confidence knowing that every sheet will look spectacular.

- Take on more lucrative short and medium print runs.

- Prepare print runs faster.

- Eliminate plates, screens and dies.

- Produce more complex jobs.

- Apply on top of a wide range of substrates, toner and offset prints.

- Job cost calculator.

- Workstation spot varnish editor.

Artificial Intelligence Smartscanner® (AIS)

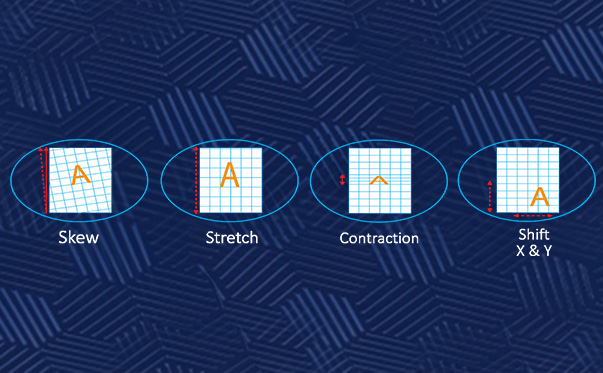

The industry leading AIS is changing the way digital printing and finishing works. The system uses artificial intelligence to create an automatic varnish registration over the pre-printed sheet, reducing setup time by more than 80% and minimising make-ready waste. Without operator intervention, the AIS makes corrections and adjustments for any defects generated in the original offset or digital print process, including sheet and image skew, shift, stretch or contraction.

Boost Your Output these optional Additions

Corona Treatment System

Increase the variety of media your AccurioShine 3600 can use and improve varnish adhesion. The Corona Treatment System (CTS) uses an electric charge to add micro-pitting to surfaces to prepare them for coating. Micro-pitting can increase wettability and adhesion, making ¡t possible to add varnish on top of a wider variety of substrates. Inserted after the paper feeder module, the CTS also contains an optional ozone cabinet, keeping your workplace clean by eliminating the need for ozone ducts. Depending on media and factors such as temperature and humidity, the CTS may not improve adhesion.

Variable Data Printing Barcode Scanner

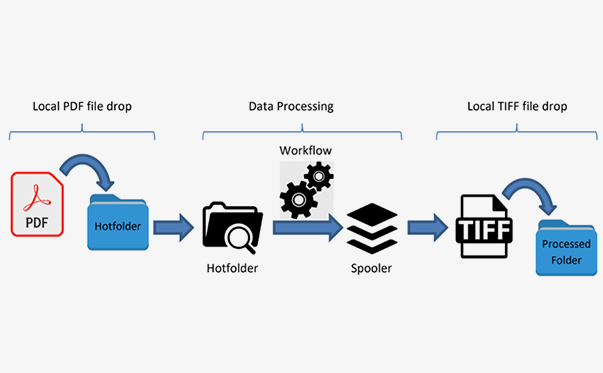

Variable Data Printing (VDP) is ideal for printing product labels, tickets or packages with small differences such as product names or barcodes. With the barcode scanner, you can make job changes as simple as scanning a barcode. The AccurioShine 3600’s barcode scanner reads barcodes from a pre-printed sheet and instantly selects the corresponding TIFF file already stored on the workstation. Combine the VDP barcode scanner with the Automatic PDF File Converter for a truly seamless workflow which takes files from PDF to the output tray in minutes.

Automatic Pdf File Converter

A separate PC that works as part of your network to automatically translate PDF data into the TIFF files required by the AccurioShine 3600. Once integrated, the Automatic PDF File Converter works to quickly move jobs forward, reducing the manual steps in starting a new print job.

Artificial Intelligence Smartscanner® (Ais) Lighting For Metallized Substrates

Add this option to enable the AccurioShine 3600 to register foil and metallic surfaces accurately. Although the AIS is equipped as standard with highly effective lighting for the vast majority of preprinted media, some substrates with metallic properties require specialised lighting to reduce glare.

In-line Hot Stamping Foil

The combination with the iFOIL One inline hot stamping foil module opens the doors to the hot foil stamping and digital embossing market. From magazine covers, books and brochures to labels, invitation cards and packaging, you will be able to offer your customers new and exceptional services.

Digital spot UV coating adds that extra dimension to any project, helping your customers stand out from the crowd. Create tactile and visual effects on typography and images, add 2D and 3D gloss With/without foil, Solid/textured effects to your final product.

Books, Book Covers, Magazines, Brochures

Offer on-demand printing and embellishment that reduces storage costs for your customers.

Greeting Cards, Business Cards, Exclusive Invitations

Create unique business or greeting cards on a range of substrates in small, medium or large quantities.

Packaging, Cartons

Produce eye-catching packaging options on-demand, with capacity for versioning and personalisation in small and medium quantities.

Direct Mail, Postcards

Help your customers to differentiate themselves with highly customised mail items that will outshine any email.

Other Applications

Personalised calendars

VIP tickets

Point-of-purchase and promotional materials

Sheet-fed labels

Menus

Rethink 3D Effects with Digital Spot UV Coating.

The AccurioShine 3600 is a ground-breaking technology for adding 2D and 3D gloss effects at a reasonable cost without the complicated steps of conventional systems. Fully digital, featuring industry-leading artificial intelligence registration technology and eco-friendly LED curing system, all at an impressively compact size. The AccurioShine 3600 allows you to offer your customers a full range of high-impact finishing effects, while raising profit margins.

AccurioShine 3600

Customers today are always looking for more from your business more value, creativity, and performance from their print jobs. The AccurioShine 3600 allows you to transform standard print jobs into engaging print products that deliver exactly what your customers are looking for – at a price that’s cost effective for your business. You will be able to easily spot coat digital prints, highlight specific areas or add 3D effects – all resulting in powerful printed communications that are more vivid and tactile.

From the global market leader and pioneer of digital embellishment technologies, the AccurioShine 3600 makes it simple for companies of any size to offer 2D spot UV and textured 3D varnish special effects – enhancements that will change your business offerings as much as its changing print itself.

Specifications

| Formats |

|

|

| Margin |

High capacity, up to 28cm or 2,200 sheets in 135 gsm.Paper feed by suction and belt |

|

| Recipe |

|

|

| Paper transport |

|

|

| Maintenance and video maintenance |

|

|

| Substrates |

|

|

| Substrate thicknesses |

|

|

| Front End System |

|

|

| General |

|

| Production speed | Up to 3500 A4/hour in 21µm |

| Useful printing width | 352mm |

| UV varnish and autonomy | The AccurioShine 3600 is delivered with a 10 liter can of varnish. Canister change during production, without machine stop |

| Varnish thickness |

|

| Tracking |

|

| In-line UV curing |

|

| Production speed | Up to 2298 A3 sheets per hour (20 meters/min)(2) |

| Hot stamping area | 35.5x100cm |

| Stamping coils |

|

| Coaxial lamp | SmartScanner AIS coaxial lamp for metallized papers |

| Variable data |

|

| Corona treatment (3)(4) | In-line system designed to optimize coating adhesion on complex printed substrates |

| Dimensions |

|

Default sheet sizes are ISO standard unless otherwise noted. All speeds are nominal.

- (1) Contact KMBME to check compatibility with your substrates / lamination / toner / acrylic varnishes

- (2) The speed varies according to the parameters used

- (3) Recommended on substrates larger than 42cm width

- (4) Recommended on papers over 250g / 250µm

System Configuration

Standard

Tray able to handle a paper pile:

- Up to 15 cm (5.9″) approximately 1,250 sheets at 135 g/m2

- Approximately 1,250 sheets at 135 g/m2

- All paper formats from Letter up to 36.4 x 75 cm (14.3″ x 29.5″)

- On-the-fly drying and curing with integrated LEDs

- No additional drying time required

- Ozone-free and without heat thanks to LED technology

- Low power consumption

- Konica Minolta’s exclusive inkjet engine technology powered by MGI

- Drop-on-Demand (DoD) technology

- Piezoelectric printheads, developed and manufactured by Konica Minolta

- Single pass printing

- Flexible printing architecture

- Full page scanner

- No crop marks required

- Coating registration from sheet-to-sheet

- On-the-fly skew, shift, contraction and stretch adjustment

- Optional lighting for metalized substrate

- 100% MGI Software Suite

- User friendly interface

- Flexible settings management

- Vacuum belt feeding system

- Handles paper pile up to approximately 2,250 sheets at 135 gsm

- Accepts paper formats from Letter up to 36.4 x 75 cm (14.3” x 19.5”)

- On-the-fly job manager

- Workstation image editor

- Catalogue of different patterns

- Job cost calculator that estimates production costs before quoting jobs

- Intuitive operation

- Eliminates customer prepress issues

- Saves time and money

Optional

- Industry-first fully digital variable data foiling

- Superior adhesion using hot foil stamping technique

- 2D and 3D embossed effects

- Compact in-line system

- Increase customer substrates compatibility with the AIS, such metallized, non-white, semi-transparent, etc

- Optional in-line system enables a broader variety of media to be used such as a wider variety of plastics

- Improves varnish adhesion and maximizes embellishment quality on digital prints

- Optional ozone filter cabinet

- The CTS Corona module can also receive an optional Ozone Filter to filter the ozone emissions of CTS module when an external air extraction is not possible.

- External Ozone filter is a solution for customer who do not want to change their facility.

- The VDP barcode camera available as an option with automatic PDF Converter to achieve the Variable data printing solution

- The barcode camera allows to read the preprinted barcode on each sheet and then, selects the corresponding .TIFF file to be printed in-fly.

- A separate PC that works as part of your network to automatically translate PDF data into the TIFF files required by the AccurioShine 3600. Once integrated, the Automatic PDF File Converter works to quickly move jobs forward, reducing the manual steps in starting a new print job.